ONEWOOD® for Architects

Design Beyond the Limits of Timber

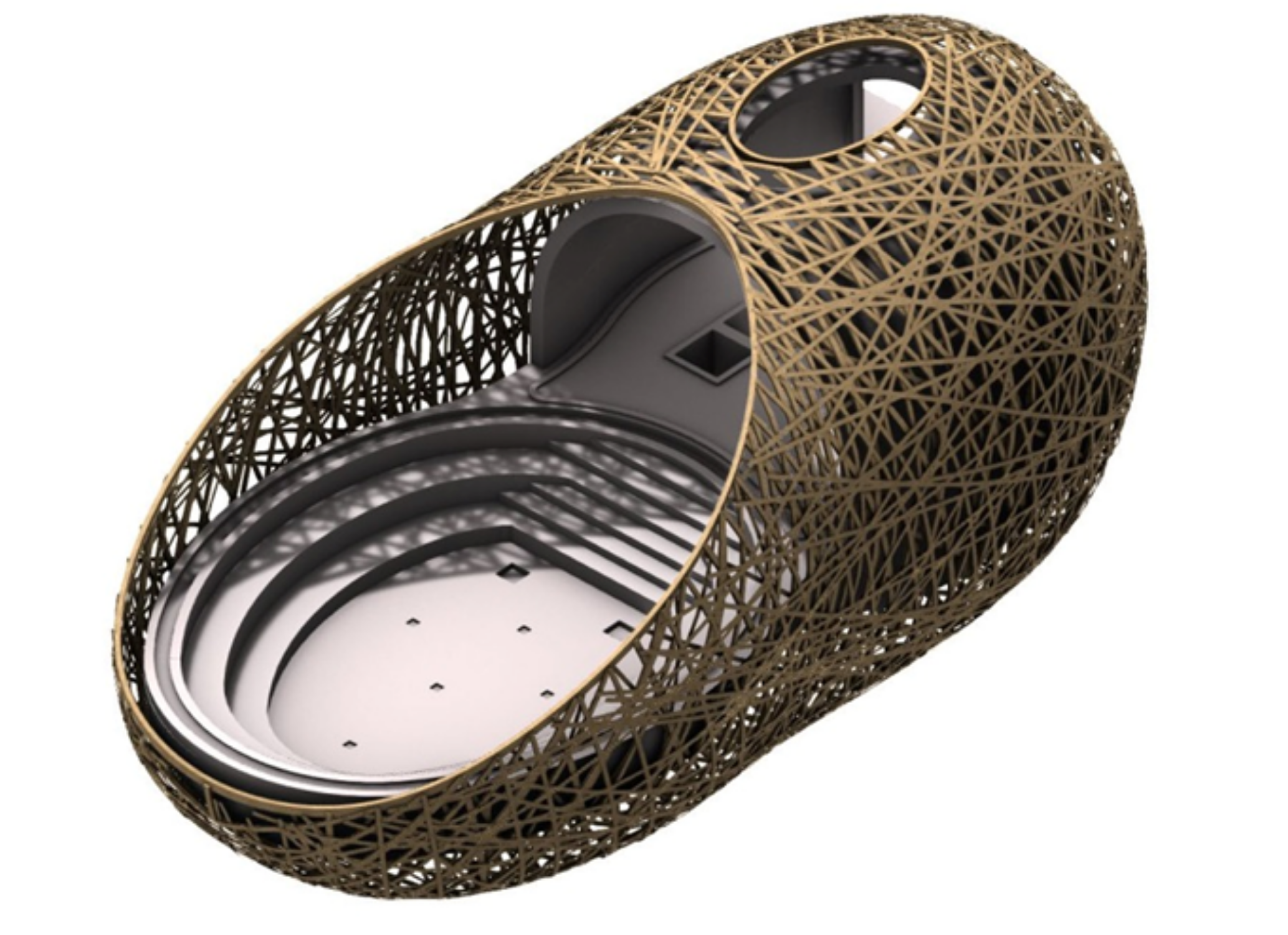

Architecture should not be constrained by material limitations.

With ONEWOOD®, architects gain the freedom to realise extreme curves, complex arches, and fluid geometries that conventional timber simply cannot achieve. Using thinner engineered strips, ONEWOOD® can be precisely formed into tight radii and continuous curves—while maintaining structural integrity, surface consistency, and visual elegance.

What makes this possible is not just the material, but the system behind it.

Our in-house technical and engineering team, supported by advanced design software and robotic CNC manufacturing, collaborates closely with architects to translate ambitious concepts into buildable reality. Complex curved connections, compound geometries, and bespoke junctions are digitally modelled, engineered, and fabricated with millimetre accuracy.

The result is a seamless integration of design intent, engineering logic, and manufacturing precision—without compromise.

Enables extreme curvature and complex arch forms

Thinner engineered strips allow tight bending radii

Uniform material behaviour for predictable outcomes

Advanced software-driven design and simulation

Advantages of Architects Choose ONEWOOD®

Robotic CNC fabrication for precise curved connections

Sustainable alternative to tropical hardwood

Natural wood aesthetics with engineered reliability

From Concept to Constructed Form

ONEWOOD® empowers architects to move beyond what timber traditionally allows—unlocking new architectural expressions through material innovation, digital engineering, and robotic craftsmanship.

If you can design it, we can engineer it.