From Architect’s Imagination to Constructed Reality

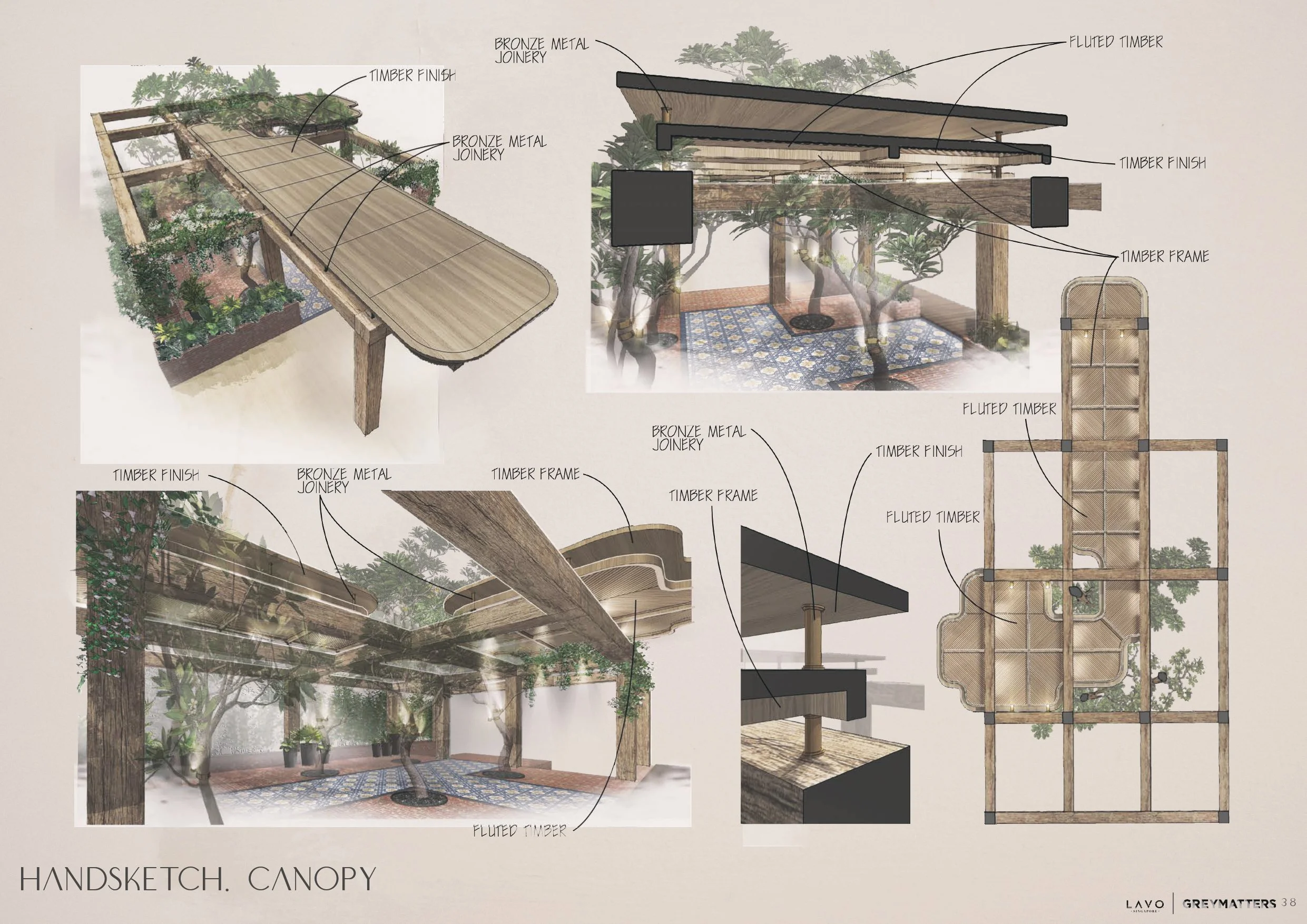

1. The Hand-Drawn Sketch: Where Vision Begins

Every architectural wonder begins with a raw, unconstrained stroke of a pen. At this stage, your vision is pure—a bold exploration of curves and organic forms that push the boundaries of spatial design. We don't just see a drawing; we decode the creative intent behind every arc, ensuring the soul of your initial sketch remains intact as we begin the journey of realization.

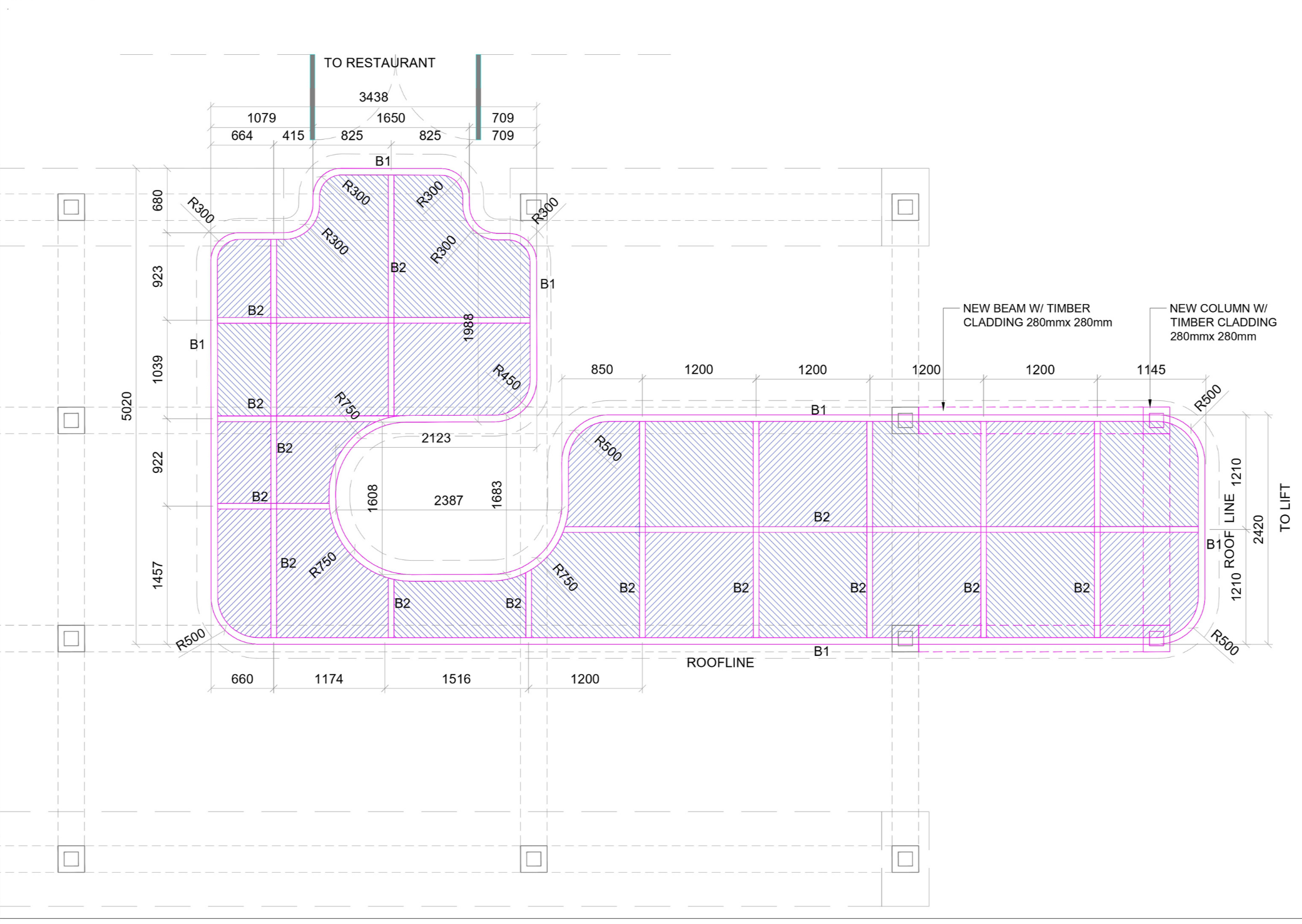

2. The Blueprint: Translating Vision into Logic

Transitioning from art to architecture requires a shift into mathematical discipline. In this phase, our technical team translates your hand-drawn concepts into precise 2D technical blueprints. This is the "rationalization" of the dream—defining exact structural spans, load-bearing requirements, and geometric coordinates. By mapping out the logic behind the curves, we establish the foundational data needed to bridge the gap between a conceptual masterpiece and a buildable, high-performance structure.

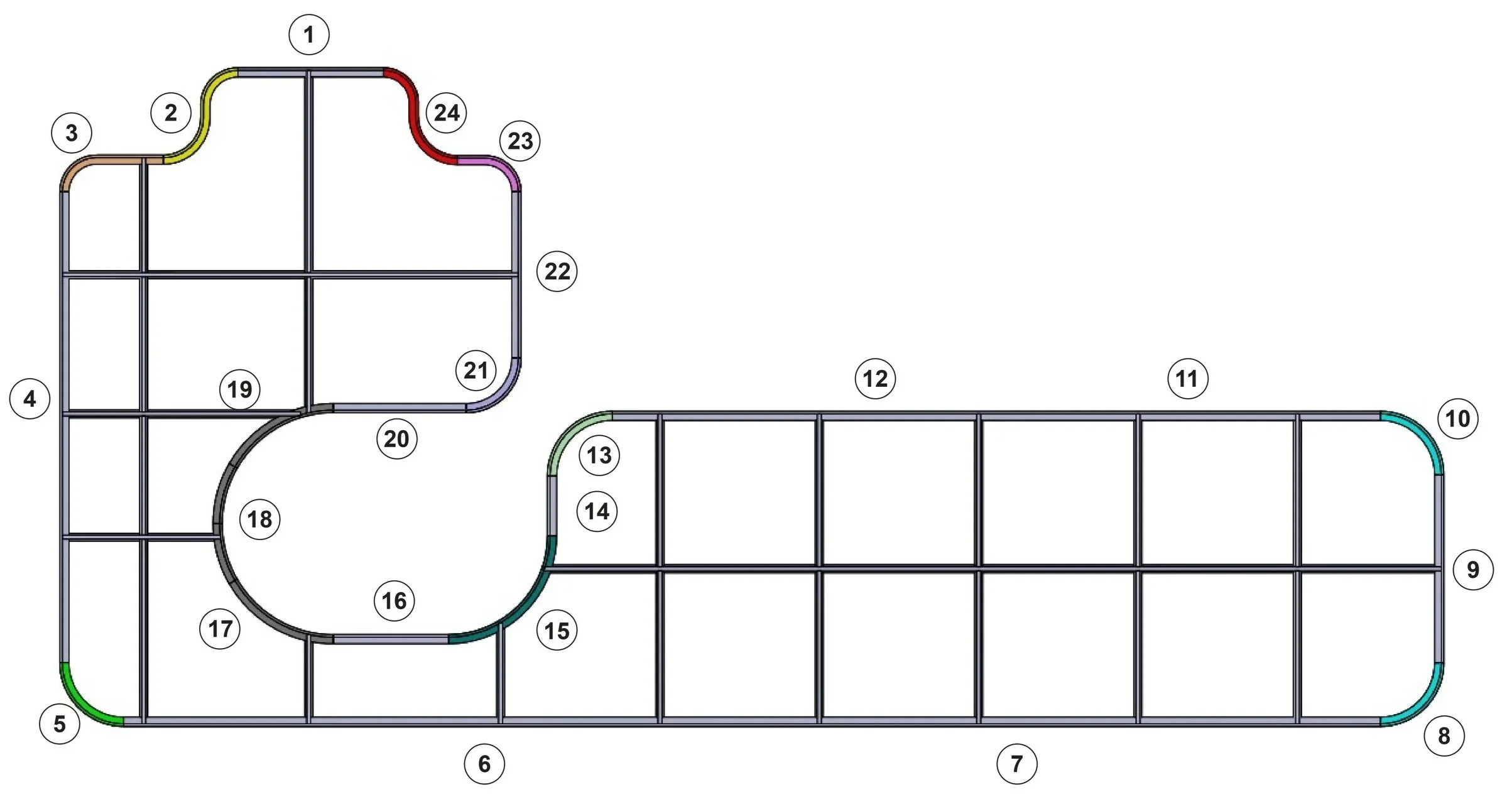

3. The Virtual Twin: 3D Metamorphosis

In the digital realm, complexity becomes clarity. Using advanced BIM (Building Information Modeling) and custom simulation software, we create a "Digital Twin" of your project. This 3D metamorphosis allows us to meticulously model every tight radius and compound junction in a three-dimensional space. We stress-test the design virtually, identifying structural optimizations and solving intricate technical challenges long before a single strip of ONEWOOD® is cut. This ensures that the most ambitious curves are not only beautiful but structurally flawless.

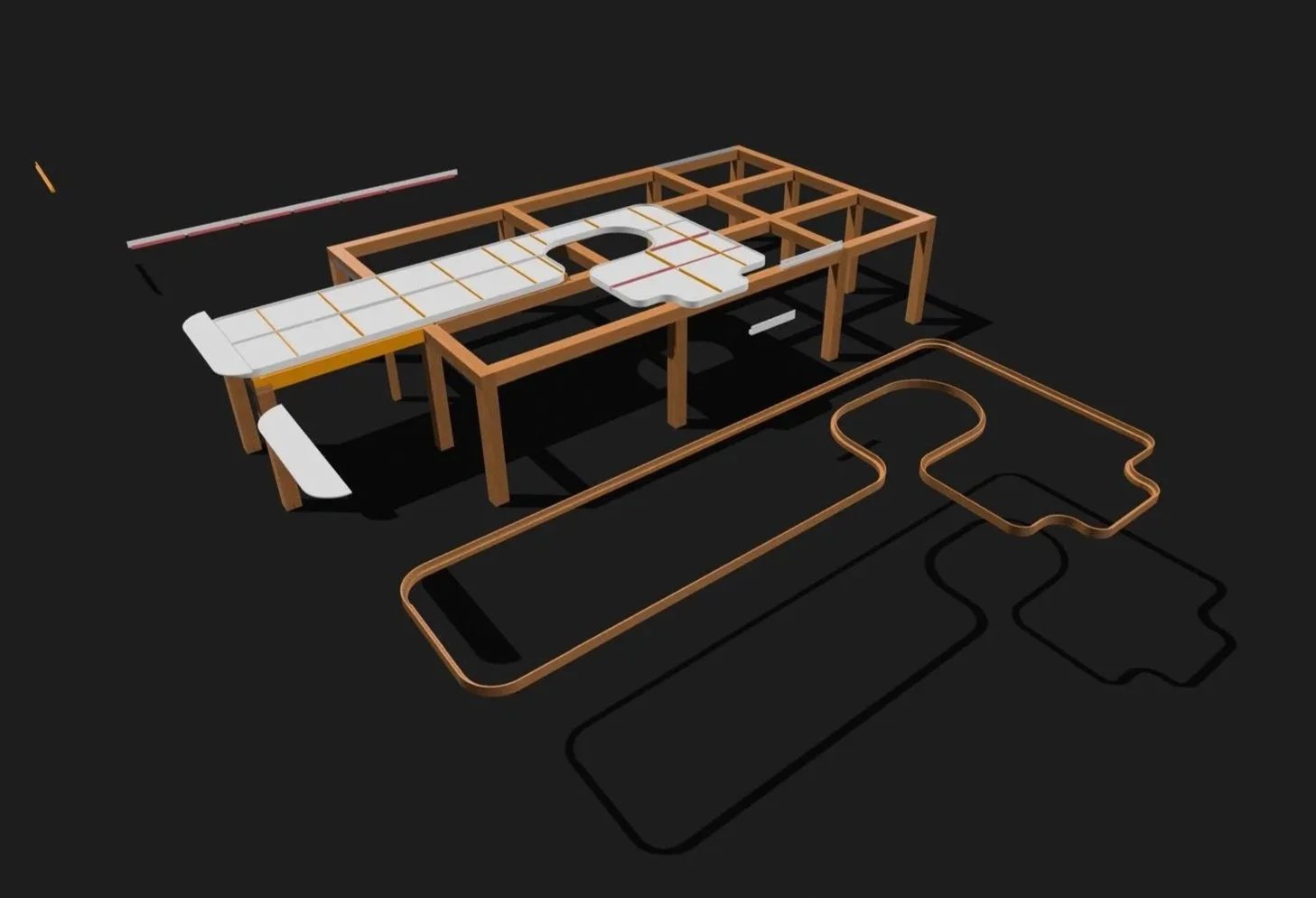

4. The Realization: From Robotics to Seamless Assembly

Witness the moment where digital data becomes physical form through a symphony of robotic craftsmanship. Utilizing our proprietary thin-layered engineering process, raw ONEWOOD® is transformed by multi-axis CNC centers with relentless accuracy. This automated precision allows us to achieve extreme curvatures and bespoke connections that traditional timber methods simply cannot reach. Every component is fabricated to millimetre tolerances, ensuring that the final "puzzle pieces" of your building fit together with industrial perfection.

5. The Assembly: Precision in Motion

Reality begins to take shape on-site during the assembly phase. Because every individual component was digitally engineered and robotically fabricated, the installation becomes a seamless process of interlocking precision. In this "halfway" stage, the structural skeleton is revealed, showcasing the rhythmic elegance of the timber ribs and joints. It is a powerful demonstration of how ONEWOOD® bridges the gap between ambitious design intent and the physical reality of the construction site.

6. The Installation: Completing the Vision

The journey reaches its destination. What started as a whisper of imagination on a piece of paper is now a tangible, enduring landmark. The finished structure stands as a perfect handshake between design intent, engineering logic, and manufacturing excellence. The curves are continuous, the joints are seamless, and the aesthetic is unparalleled. This is the ONEWOOD® legacy: a world where if you can design it, we can engineer it—realized without compromise.